Rock rails are vital safety features for off-road vehicles, especially those in the Brownsville fleet, which faces challenging terrain. Advanced truck diagnosis tools enable mechanics to maintain and ensure these systems' integrity, using precise technology for proactive maintenance. Installing rock rails in regions like Brownsville boosts commercial fleet safety, reducing rollover risks and side-impact collisions, despite initial costs and maintenance needs. The Brownsville fleet's innovative use of diagnosis tools sets industry standards, prioritizing driver well-being and contributing to safer road conditions.

Rock rails, an essential safety feature on trucks, act as a barrier between vehicles and potentially hazardous fixed objects along roadsides. This article delves into the definition, purpose, and impact of rock rails, highlighting their critical role in preventing damage and enhancing driver safety. We explore the innovative approaches of the Brownsville Fleet in integrating these systems and examine advanced truck diagnosis tools used to assess their effectiveness. Additionally, we discuss the benefits and challenges associated with implementing rock rails.

- Understanding Rock Rails: Definition and Purpose

- Brownsville Fleet's Role in Truck Safety Features

- Diagnosing Rock Rail Systems with Advanced Tools

- Benefits and Challenges of Implementing Rock Rails

Understanding Rock Rails: Definition and Purpose

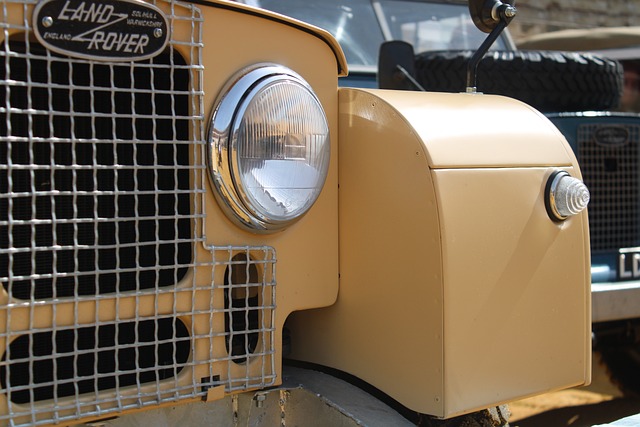

Rock rails are an essential safety feature designed to protect vehicles, particularly in off-road or rugged terrain driving. They are robust metal bars or beams strategically placed along the sides of roads or tracks to prevent vehicles from veering off and rolling over. This simple yet effective mechanism is especially crucial for heavy-duty vehicles like the Brownsville fleet, which often navigate challenging road conditions.

For truck operators and mechanics using diagnostic tools like those offered by Brownsville, understanding rock rails’ purpose is vital. These tools can help identify potential issues or damage to these critical components, ensuring the safety of drivers and maintaining the integrity of the vehicle during demanding operations.

Brownsville Fleet's Role in Truck Safety Features

The Brownsville Fleet plays a significant role in shaping truck safety features through its extensive experience and innovative spirit. This fleet, known for its robust and reliable vehicles, leverages advanced truck diagnosis tools to identify potential hazards and implement necessary safety measures. By utilizing cutting-edge technology, they can predict and prevent accidents, ensuring the well-being of drivers and other road users.

Through continuous monitoring and data analysis, the Brownsville Fleet’s diagnostic tools help in identifying common issues and areas for improvement. This proactive approach not only enhances the overall safety of their fleet but also contributes to the development of more robust safety standards within the industry. By staying at the forefront of truck diagnosis, they are revolutionizing road safety and setting a benchmark for others to follow.

Diagnosing Rock Rail Systems with Advanced Tools

In today’s digital era, diagnosing rock rail systems on vehicles like the Brownsville fleet has evolved significantly thanks to advanced truck diagnosis tools. These cutting-edge technologies offer precision and efficiency in identifying issues with rock rails, a crucial safety feature in off-road vehicles. With specialized software and sensors, mechanics can swiftly scan for codes, monitor sensor data, and visualize system performance, enabling them to pinpoint problems accurately.

Brownsville fleet managers leverage these tools to maintain optimal performance and safety standards. Advanced diagnostics allow for early detection of wear and tear, ensuring timely repairs. This proactive approach not only extends the lifespan of rock rail systems but also enhances the overall reliability and safety of the fleet during rugged operations.

Benefits and Challenges of Implementing Rock Rails

Implementing rock rails offers several benefits, especially in regions prone to harsh weather conditions or terrain instability. For example, in areas like Brownsville, where fleet managers face challenging road environments, rock rails can significantly enhance safety. They provide additional support for vehicles, reducing the risk of rollovers and protecting against side-impact collisions, which is crucial for commercial fleets like truck operations. These barriers are particularly useful on winding roads or steep slopes, ensuring that trucks maintain their lanes and minimizing damage during accidents.

However, there are also challenges associated with rock rail installation. One significant consideration is the initial cost, which can be high, especially for extensive implementations. Fleet managers need to invest in diagnosis tools and specialized equipment to assess the terrain accurately and plan the most effective placement of these rails. Additionally, ongoing maintenance is required to ensure the integrity of the rock rails, which might pose a challenge for remote or hard-to-reach areas. Despite these hurdles, the long-term benefits, such as reduced insurance costs and decreased vehicle damage, make rock rails an appealing solution for fleet safety in demanding environments like Brownsville.

Rock rails, as integral safety features on trucks, play a significant role in preventing damage and enhancing driver control. As demonstrated by the innovative practices at Brownsville Fleet, integrating these systems can significantly reduce accidents and costs. Utilizing advanced truck diagnosis tools for maintenance and repair further ensures optimal performance and longevity of rock rail systems. While there are challenges to implementation, the benefits—from improved safety to cost savings—make rock rails a beneficial addition to modern trucking infrastructure.